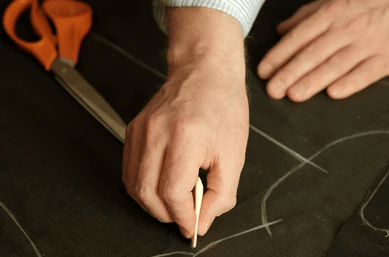

We view pattern making as an art form—the process of transforming a flat piece of fabric into shapes that align with the natural curves of the human body. It serves as the vital link between design and production, turning creative concepts into wearable products.

The cutting process is crucial in the production of leather products. Precision, efficiency, and quality are essential at this stage to ensure that each piece is perfectly crafted for the final product.

Lining cutting is a key step in producing leather jackets and gloves. Different types of lining are carefully cut based on the seasonality and specific requirements of the garments, ensuring comfort and durability in every piece.

We employ advanced machines for stitching our products, while more intricate areas are hand-stitched by our skilled craftsmen, ensuring precision and quality in every detail.

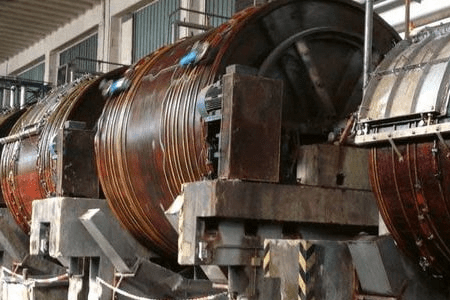

Leather items undergo washing tailored to achieve the desired final effect. Various washing techniques are used to create unique finishes, enhancing the look and feel of each leather garment.

We apply various waxing techniques to our finished leather goods. This process involves a thin coating of a paste-like mixture of dyes or pigments, adjusting the color and providing a unique shine to the products.

Each product undergoes thorough inspection and quality checks before being prepared for shipment. Once inspected, all items are stored in our advanced warehouse, equipped with an automatic hanging system to optimize efficiency and organization.

In accordance with the buyer’s instructions, garments are poly-packed by color, size, and type, then bundled and placed into custom-made cartons tailored to client specifications. Each carton is clearly labeled for easy identification. The products are then shipped to various global brands, ensuring timely and accurate delivery.